Security holograms help protect items from being copied or faked. These special labels often carry custom designs and can include smart codes that connect to digital systems. Businesses across many industries now depend on security holograms to protect products, documents, and packaging. With the growing need for safety and proof of originality, these small stickers do significant work. They are eye-catching, but more importantly, they carry multiple layers of protection that are difficult to break. Creating them involves careful steps and precise tools. In this guide, we will walk through how to make security holograms, what materials are used, how QR code stickers integrate into the process, and why they matter in today’s world.

What is a Security Hologram?

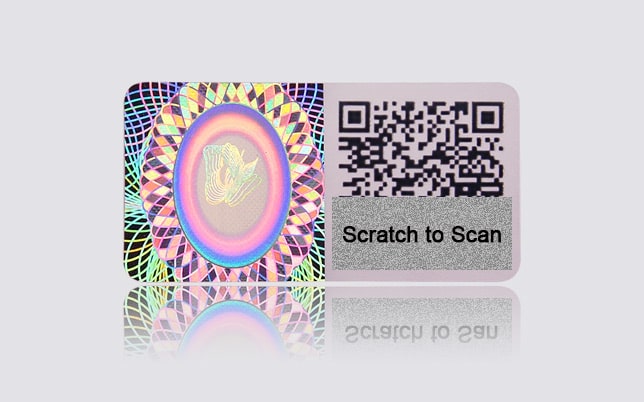

A security hologram is a label featuring unique, three-dimensional images that display different patterns when tilted. These are not only for aesthetic purposes; they serve the critical function of authenticating an item’s legitimacy. They are commonly placed on ID cards, product packaging, and official documents. When combined with a product QR code or integrated into a QR code system, they further streamline the verification process. Security hologram stickers cannot be replicated using standard printers. They often include microscopic details, concealed marks, or codes that are only decipherable by experts. These features are essential for preventing counterfeiting and for protecting both consumers and brands.

Materials and Tools Needed

To build security holograms, makers use special materials and equipment. Each item plays a role in shaping, copying, and finishing the label.

Main Materials

- PET (polyester) film: strong and smooth base for images

- Adhesives: to stick the hologram onto surfaces

- Nickel shim: used to stamp the design

- Silicon paper: used in lamination

Main Tools

- Dot-matrix hologram machine: creates the master image

- Electroforming tank: forms the nickel stamp

- Embossing machine: presses the image onto the film

- Coating machine: spreads glue or oil

- Die-cutting machine: slices labels into shape

- QR code printer: adds product QR codes and QR code stickers

- Slitting machine: splits large rolls into smaller ones

Together, these shape raw film into beneficial and protective holograms.

Holograms play a vital role in product protection; explore how they secure items with QR code stickers and tamper-proof layers in our guide on how holograms are used for security.

How to Craft Effective Hologram Security Stickers

Creating effective security holograms requires meticulous work, high-end equipment, and a well-considered design. The goal is to make them difficult to copy while ensuring they are easy to scan or verify. These stickers must appear clear, hold intricate patterns, and adhere reliably to products. Printing QR code stickers directly onto these holograms adds a sophisticated layer of security. The product’s QR code directs customers to a website or verification portal, transforming the sticker from a purely visual element into a digital one as well.

Let’s explore the five key steps that bring hologram security to life, from the initial design to the final application.

Step 1: Designing the Hologram

First, designers sketch the image that will become the hologram. This could be a company logo, pattern, or code. The sketch must include fine lines and curves that regular printers cannot copy. Once approved, the image goes into a dot-matrix machine. This tool burns the design into a master plate with high detail, sometimes up to 2450 dpi. The machine’s precision allows it to record every curve clearly. This original design becomes the base of all future stickers. Clear design helps the sticker reflect light differently, making seeing changes from side to side easier.

Step 2: Master Hologram Creation

After the design is finished, a plastic film carries it into a big electroforming tank. Here, metal forms on top of the image through a slow chemical reaction. A nickel shim gets shaped with the same design in about two to three hours. This nickel plate acts like a stamp or mould. It must stay clean and solid, because it presses hundreds or thousands of holograms. Using the nickel shim keeps every sticker the same. Once it gets made, workers dry it, polish it, and store it safely. This step gives the sticker its secure and lasting pattern.

Step 3: Replication & Printing

The nickel shim now enters the embossing machine. A strong press stamps the hologram image onto rolls of PET film. The machine uses heat and pressure to carve the design deeply into the film. After that, a coating machine spreads glue or silicone oil on the back. This step allows the sticker to stick firmly later. Next, a die-cutting machine cuts out each label in neat shapes, whether square, round, or custom. Some stickers stay in rolls; others get cut into sheets. Everything moves fast and smoothly, so the images remain clear and the shapes stay sharp.

Step 4: Integration with QR Code Systems

Once the sticker takes shape, a QR code system adds a product QR code. This code contains the product name, batch number, or website link. Machines print this code directly on top of or beside the hologram. This makes a hybrid sticker, half visual, half digital. When someone scans it, they can confirm if the product is real. QR code stickers make checking items quickly easy for customers and stores. Each code stays unique and matches the product it sticks to. This step connects real-world safety to smart tracking and record-keeping online.

Step 5: Application on Products

Now that the security hologram stickers are finished, they move to packaging. Workers or machines attach them to items like boxes, bottles, or cards. The stickers must stay smooth and stick well, so no part peels off. Some products may need stickers on the top flap; others on seals or labels. Once applied, the product looks secure and ready for sale. The QR code sticker works immediately; scanners or phones can read it. This final step covers the whole process and prepares the product for the store shelf or shipping.

Different Methods of Creating Security Holograms

Makers can build security holograms in a few ways. Each method gives different styles, depths, and costs.

Dot-Matrix Method

This uses lasers to etch the design into film with ultra-fine points. It allows complex designs and high details. Dot-matrix holograms reflect light at many angles.

2D/3D Layering

Flat images are stacked in layers in this method to give a deep look. They often show a company name in front and a design in the back. Tilting shows different layers.

Electron Beam Lithography

This uses beams to shape super fine designs. It’s expensive but makes patterns that are very hard to copy.

Digital Mastering

Computer software draws the whole design, which is transferred onto film using digital tools. This allows flexible design changes and fast editing.

Each method needs precise tools and skilled people to operate them. Choosing the correct method depends on the product type and security level required. Sometimes, a mix of methods works best.

Security Features Embedded in Holograms

Good hologram security means packing many layers of safety into a small label. These features include:

- Microtext: Tiny words or numbers that can only be read with a lens

- Hidden Images: Pictures that only appear under certain light

- Colour Shifting Ink: Colours that change as you move the sticker

- Guilloche Patterns: Wavy lines that are hard to scan or copy

- Serial Numbers: Unique codes that track every item

- QR Code System: Printed product QR code that links to a digital page

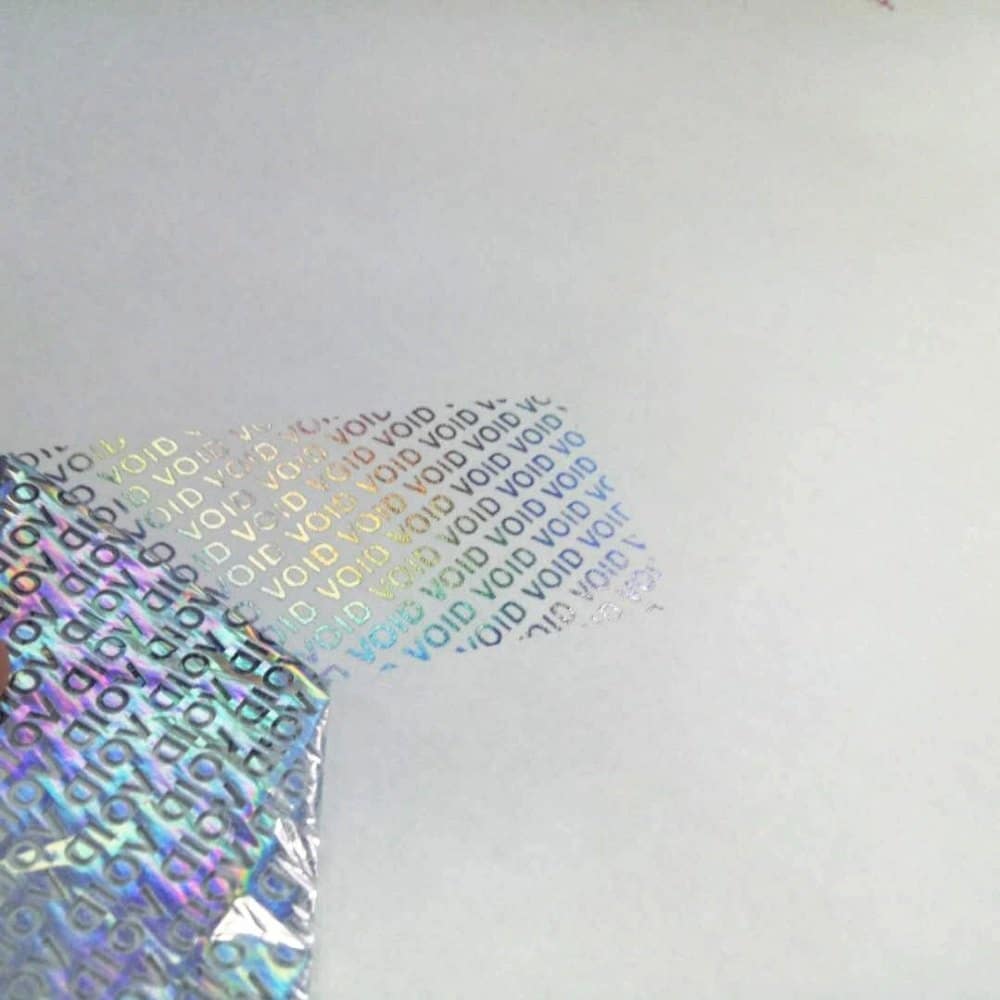

Together, these tools keep fake copies away. Some holograms also include tamper-evident parts that break when someone tries to peel them off. Each part builds trust between seller and buyer.

Conclusion

Creating security holograms takes careful steps and state-of-the-art tools. Every stage must stay accurate from the first drawing to the final product QR code printing. Using the right machines and designs ensures the labels do their job well. When QR code stickers combine with sharp holograms, they give strong protection and easy scanning. Whether for packages, papers, or branded items, these stickers help prevent fakes and build trust. Choosing strong hologram security tools gives any product a competitive edge. If your items need to stay real, and your brand needs to stay safe, then a solid security hologram is your best choice.